Overview of…

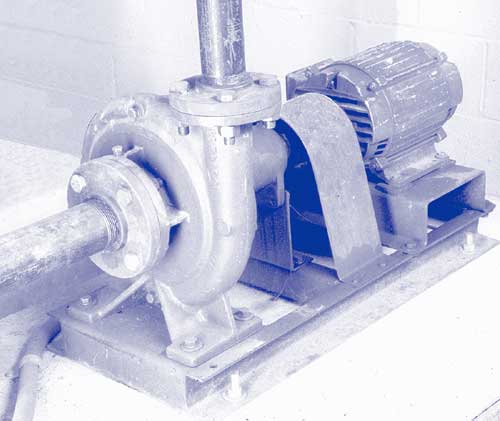

Note 35. Centrifugal Pumps

Centrifugal pumps are one of the mainstays of modern civilization, notable for their simplicity. As they hum quietly, they also consume large amounts of energy. They are major energy users in commercial facilities that have hydronic HVAC systems, and they are prime energy users in many industrial operations.

Many of the energy conservation measures in the Energy Efficiency Manual involve pumping. This Note explains the efficiency aspects of centrifugal pumps. It gives you a basis for selecting pumps for maximum efficiency in typical applications, and for improving the efficiency of existing pump installations.

Here you will learn how pumps operate. The work of pumping is done by the impeller. The impeller speed and diameter determine the flow rate, the pressure output, and the power requirement. Also, the density or specific gravity of the fluid being pumped determines the pressure and the power requirement. Simple pump “affinity laws” state these relationships.

“Pump curves” show the relationship between pressure, flow rate, power input, and efficiency. You will see how to use pump curves to match a pump to its system curve for maximum efficiency. Throttling the pump output has a large effect on efficiency. The pump curves show the relative efficiency of throttling and trimming the impeller diameter.

The maximum efficiency of a pump is determined by the shape of the impeller, and by the matching of the impeller to the pump casing. These are expressed by the “specific speed”, which is explained here. Other efficiency factors are internal leakage and recirculation, the pump size, the smoothness of the internal passage, compromises in the design of the impeller to handle dirty fluids, and the viscosity of the fluid being pumped.

Click here to return to the Table of Contents