Overview of…

Note 32. Compression Cooling

Most air conditioning, refrigeration, and industrial cooling equipment worldwide operates by using a refrigerant compression cycle. The Energy Efficiency Manual gives you a wide range of efficiency improvements for compression cooling equipment and systems. This Note gives you a solid introduction to the subject.

There is fierce competition among manufacturers with different designs, and each touts its own advantages while being silent about its own disadvantages. The Note will help you to navigate through the competing claims by understanding the principles of compression cooling. It will enable you to ask the right questions when selecting new equipment, and it will give you a solid foundation for making efficiency improvements to existing cooling systems. You will learn about the factors that affect cost, safety, space requirements, maintenance, environmental protection, and other issues.

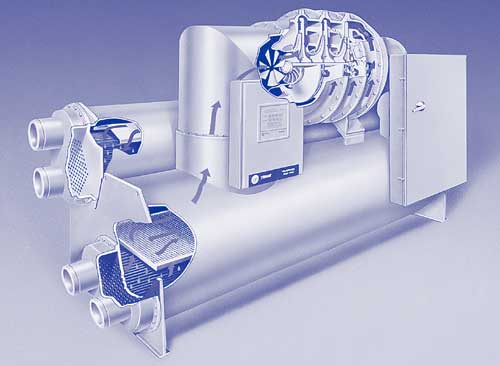

This heavily illustrated Note explains how compression cooling works, the five basic elements of compression cooling systems, and common system arrangements. The types of compressors are explained and illustrated, including centrifugal, reciprocating, screw, scroll, and vane compressors. Important issues include the methods of modulating output, compatible types of refrigerants, interstage heat transfer, the number of stages of compression, and compression ratios.

Different types of motor drives are explained, including open external, hermetic, and semi-hermetic motor installations. Reciprocating engine and steam turbine drives are discussed.

The evaporator design can have a major effect on efficiency. The Note explains flooded evaporators, liquid overfeed, expansion valves, capillary tubes, and the effects of evaporator superheat. Parallel and series evaporator layouts are compared.

The operating temperatures of a cooling system have a large effect on efficiency. The effects of evaporator temperature and condensing temperature are illustrated. Condensate subcooling is explained.

Click here to return to the Table of Contents