Overview of…

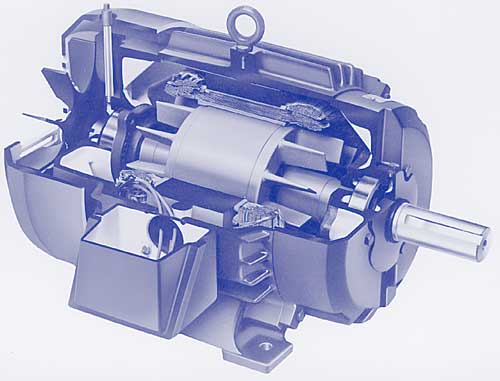

10.1 A.C. Induction Motors

This part of the Energy Efficiency Manual shows how to improve the efficiency of your alternating current (AC) induction motors. Motors consume more electricity than any other type of equipment, perhaps more than half the electricity produced in the world. By far the largest portion of motor energy is consumed by large motors. Almost all of these are 3-phase induction motors. Improving motor efficiency is a major opportunity both in the design of new facilities and in existing facilities.

In the industrial sector, large, replaceable motors account for a majority of total energy consumption. In the commercial sector, motors are smaller in size and they account for a smaller fraction of total energy consumption, but they are still major candidates for efficiency improvements. In the residential sector, separately replaceable motors represent only a small fraction of total energy consumption, and opportunities to upgrade them are infrequent.

Here you will learn the essential issues in selecting and applying AC induction motors. Rewinding existing motors is compared to purchasing entirely new high-efficiency motors. The features of high-efficiency motors are explained. Motor efficiency ratings are explained, including NEMA efficiency ratings and other rating systems. You will learn how to use the simple and powerful MotorMaster computer program to select motors for both full-load and part-load efficiency.

You will learn how to specify motors in new construction, and when to upgrade motors in retrofit projects. The essential motor characteristics are explained, including full-load efficiency, part-load efficiency, service factor, motor torque ratings, operating temperature limits, voltage, power factor, locked-rotor and starting amperage, enclosure types, and frame and face types. Additional features for motors used with variable-speed electronic drives are explained.

You will learn the importance of motor phase balance and how to correct it.

Click here to return to the Table of Contents